Pressing System

Press Box Girders Pneumatically on the Assembly Table

Glued Box Girders & Ribbed Slabs

as roofs & floors in modern timber construction

More Space

- Freespans of 7-8 m thanks to improved stiffness

- Higher rooms thanks to section reduction up to 30%

Added Value

- Instead of purchasing other floor solutions

- Increases order volume by 30%

- Use the same assembly line as for wall prefab

Cost-Effective Product

- Ready-to-fit Construction

- Structural 3-ply panel as finished surface

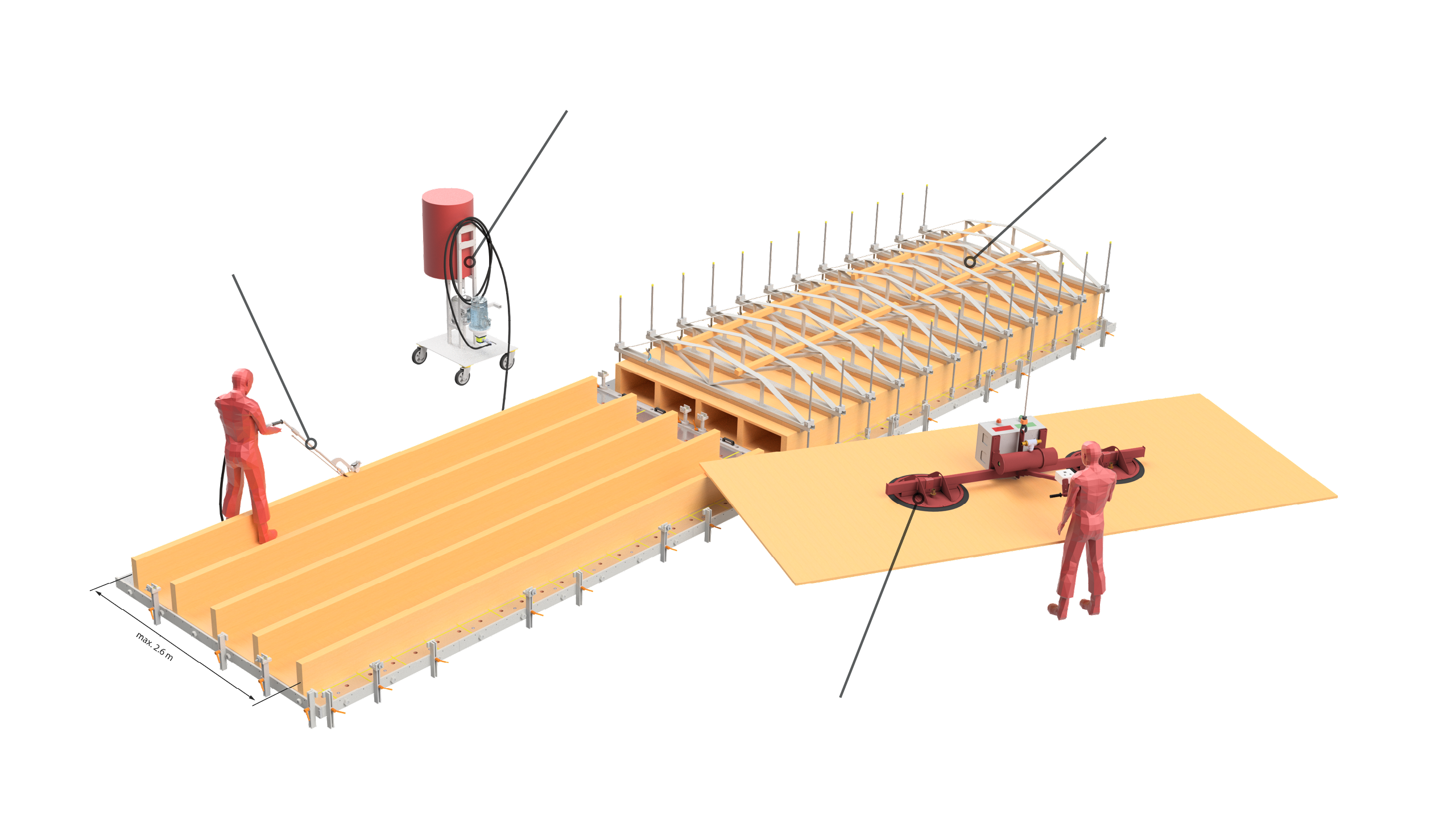

Guide System

With rollers and side stop. For linear application in ergonomic posture.

Vacuum Lifter

The indispensable tool for large format 3-ply panels

Manual Adhesive Applicator

Adhesive directly from the container. Save up to 50% of cost.

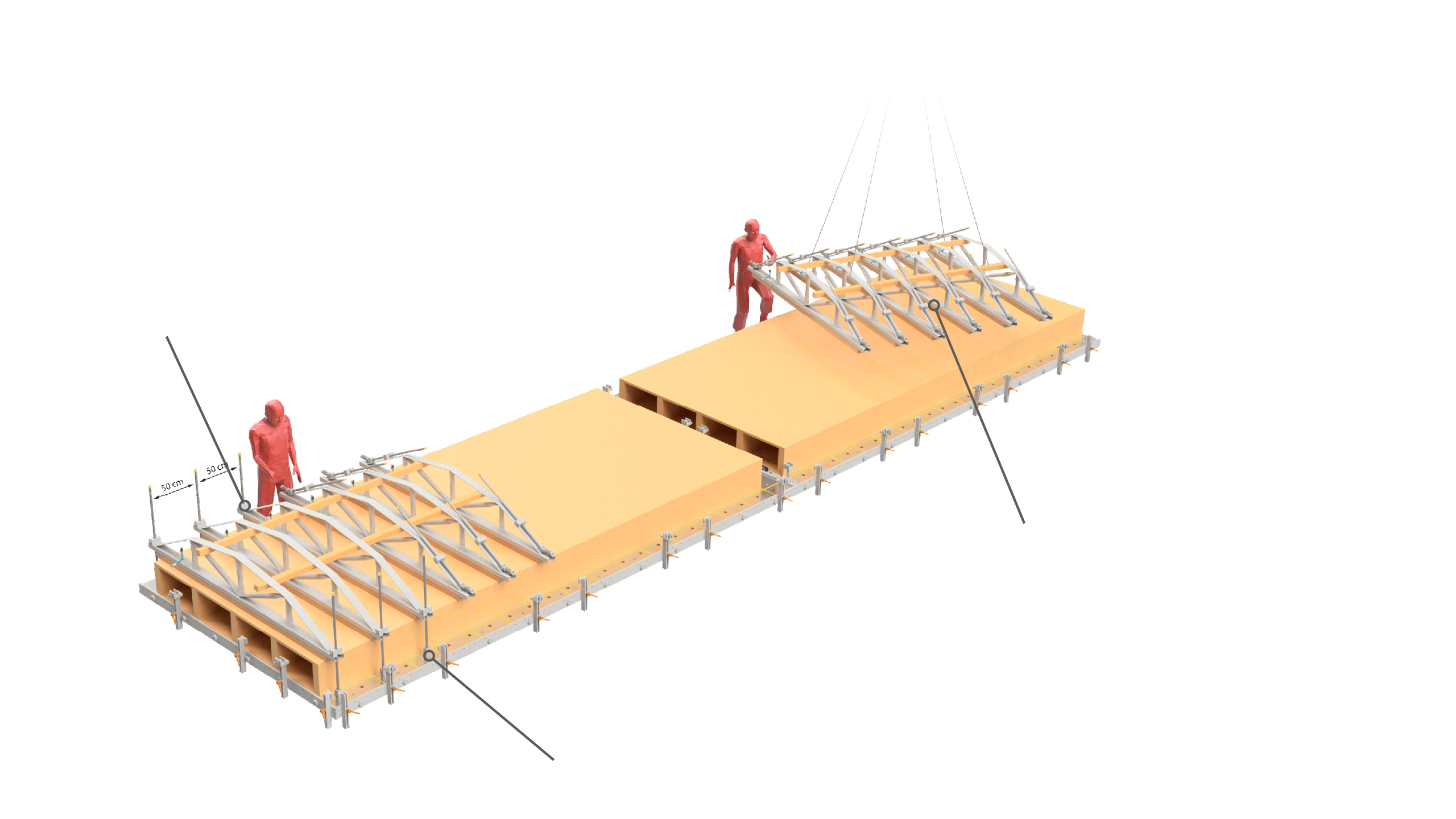

Alternating Cycles

One element is still being pressurized whilst a new one is being manufactured.

Expansion Anchors

Plugging the tie rods in a hole and pulling on them clamps them automatically

Pressing Units

The pressing units are often linked together as bundles to facilitate handling

Quick-Lock Nuts

Holding down the button decouples the lock nuts to displace them rapidly on the rods

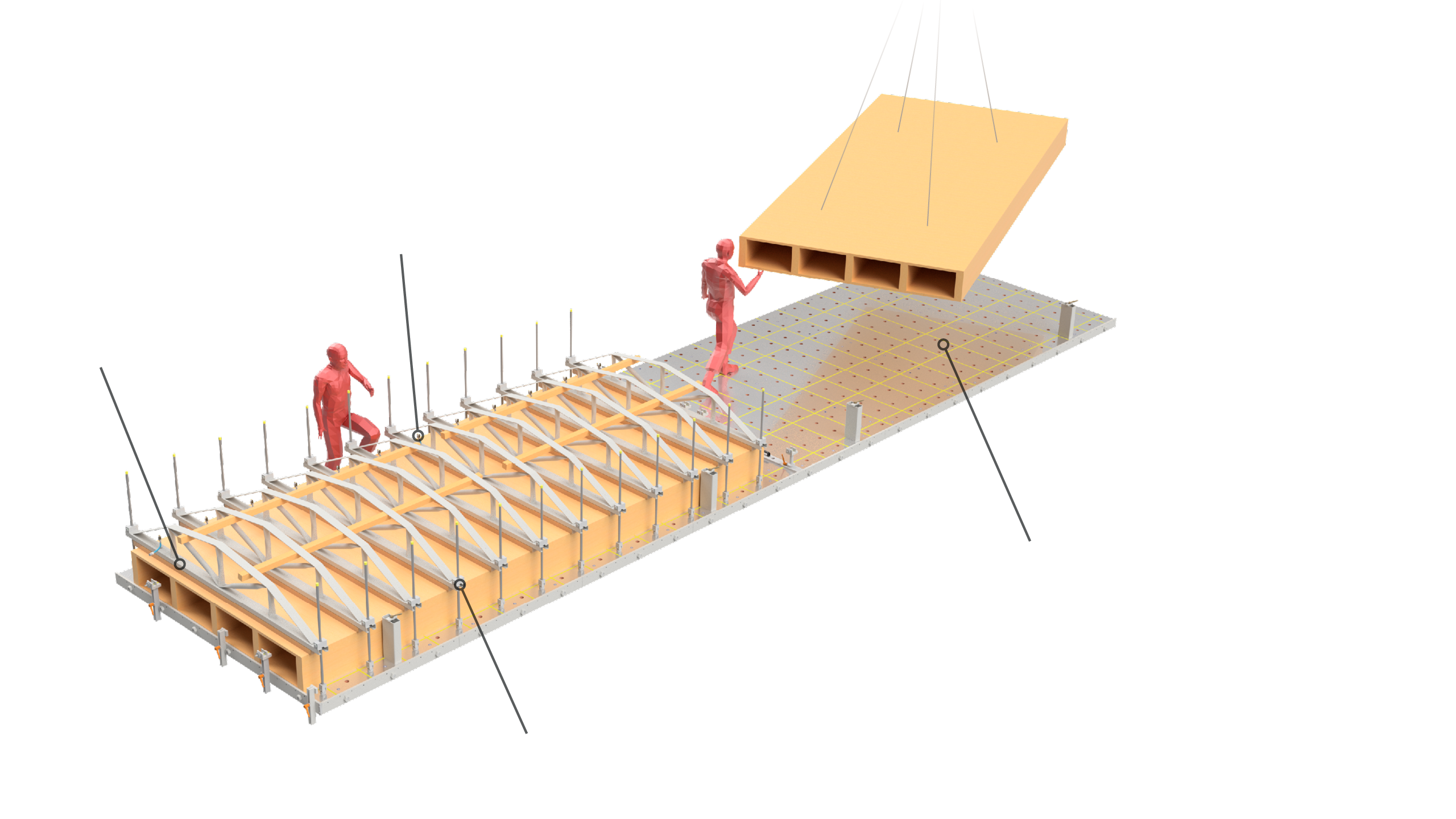

Pressing Hose

The pressing hose distributes the pressure evenly and re-pressurizes when the surplus adhesive oozes out

Alternating Cycles

A new element can be manufactured while the other is pressurized

Series Connection

The pressing units are connected one after the other and activated

Adjustable Pressure

The air pressure is regulated from 0-3 bar, which results in a max. force of 39 kN (3.9 t) per unit

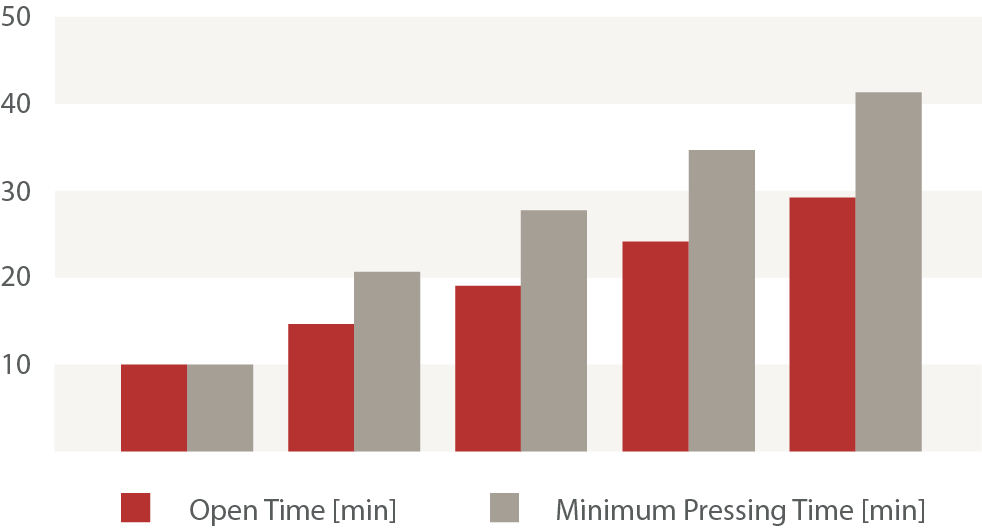

How long does it take?

=

What type of adhesive is used?

1K PUR adhesives have relatively short curing times.

The Open Time indicates the time available for assembly and pressurizing the element.

Tip:

If the space between beams are filled in with insulation, electrics or other it is more advantageous to glue bottom and top panel during different cycles in order to stay with shorter open times. This leaves more time to fill the interiors properly and decreases overall manufacture time due to shorter pressing times.

Pneumatic Pressure:

The Advantages

No Turnover

The element can be produced in one cycle. Without need to turn it over for fixing the screws.

No Screws

Save on material and assembly time while obtaining surfaces without screw holes in them.

On the Same Table

Make Timber Frames and Box Girders on the same assembly table and save big on investment.

Monitored Pressure

A constantly monitored pressure results in safe structural products.

The pneumatic system re-pressurizes the element as soon as the adhesive oozes out and the glue joint is thinning out.